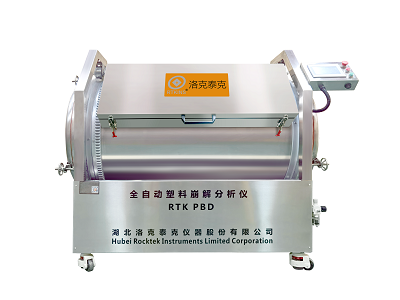

RTK PBD automatic plastic disintegration analyzer

RTK PBD automatic plastic disintegration analyzer

Disintegration tests were conducted under defined, standardized conditions for pilot-scale composting. The test material is mixed with fresh biomass waste in precise proportions and placed in a defined composting environment. The microbial populations prevalent in nature naturally trigger the composting process and the temperature increases accordingly. Composting materials should be turned over and mixed regularly.

Brand: RTK

Model: RTK PBD automatic plastic disintegration analyzer

Product introduction

Disintegration tests were conducted under defined, standardized conditions for pilot-scale composting. The test material is mixed with fresh biomass waste in precise proportions and placed in a defined composting environment. The microbial populations prevalent in nature naturally trigger the composting process and the temperature increases accordingly. Composting materials should be turned over and mixed regularly. Regularly monitor temperature, pH, and gas composition, which should meet standard requirements to ensure adequate and suitable microbial activity.

The composting process continues until the compost is fully stable, typically after about 12 weeks. The compost is observed regularly from the appearance to monitor the adverse effects of the test material on the composting process. To determine the compost maturation at the end of the test, sift the compost and test material mixture with a 2mm and 10mm sieve. The disintegration of the test material was evaluated by the ratio of the amount of test material fragments to the total dry solids on the 2mm test screen. The compost obtained at the end of the composting process can also be used for further tests, such as chemical analysis and toxicity testing

Applicable standard

(1) For plastic biodisintegration performance analysis

(2) Meet ISO 16929-2021

(3) Meet GB/T19811-2005

Disintegration test validity index

(1) The maximum compost temperature is lower than 75℃ in the first week after the start of the test, and lower than 65℃ thereafter。

(2) The temperature is kept above 60℃ for at least a week;

(3) The temperature should be kept above 40℃ for at least four weeks;

(4) During te test, the pH value increased to more than 7, and did not decrease to less than 5;

(5) After 12 weeks, the composting degree of blank control biomass waste is between IV-V(" Rottegrad "), its volatile fatty acid content is less than 500mg/Kg, or other appropriate parameters are used to ensure the completion of the normal composting process.

Technological advantage

(1) Seal and insulation design;

(2) Equipped with automatic mixing device, automatic heap turning, saving manpower;

(3) The use of porous tube intake is conducive to full contact between oxygen and compost;

(4) Equipped with automatic humidification device to maintain the humidity of the compost;

(5) The reactor body is provided with a plurality of temperature sensors to facilitate temperature monitoring;

(6) The reactor body is provided with a plurality of sampling ports for easy sampling analysis, such as pH;

(7) Equipped with oxygen sensor, humidity sensor. It can also be equipped with carbon dioxide sensor and methane sensor according to demand;

(8) Touch screen display and control, data download function;

(9) Equipped with multiple grids to realize the test of multiple samples.

System parameter

Technical parameter

(1) Stainless steel drum design, patented products;

(2)PLC touch screen control, can download the operating parameters;

(3) Built-in reactor: 48L*6, equipped with 3 air intakes;

(4) Turning mode: drum type, program control automatic turning, turning interval, time and direction can be adjusted;

(5) Humidification: ultrasonic humidification;

(6) Temperature sensor: 0-80℃, accuracy ±0.5℃;

(7) Oxygen sensor: 0-100%, accuracy <±3%F.S.

(8) Humidity sensor: 50-95%, accuracy ±5%;

(9) Power supply: 220V, 16A;

(10) Dimensions: 1970W*1100D*1590H Weight: 425kg.

Configuration list

(1) 1 set of main engine (built-in reactor);

(2) 1 set of air compressor;

(3) 1 set of temperature, humidity and oxygen sensors;

(4) 1 set of humidification system.